New Energy

BMS Battery Management Control System

Date:2025/1/2 22:06:52 Hits:53

Test object: (BCU)

Test requirements

- Quiescent current, working current test

- Power supply voltage test

- Can teminal resistance & communication test

- Qinsulation detection function test

- Frequency signal acquisition function

- Collision detection function test

- High voltage interlock function test

- Current acquisition function test

- Temperature signal sampling test

- CC signal test

- Relay load test

- Battery pack total voltage acquisitionfunction test

- High and low effective digital input signal test

- Finished driving program burning

Test object:(CMC/CSC)

Test requirements

- Quiescent current,working current test

- Output power supply voltage test

- Can communication test

- Analog cell voltage sampling test

- Temperature signal sampling test

- Equalization current test

- Finished product driving program burning

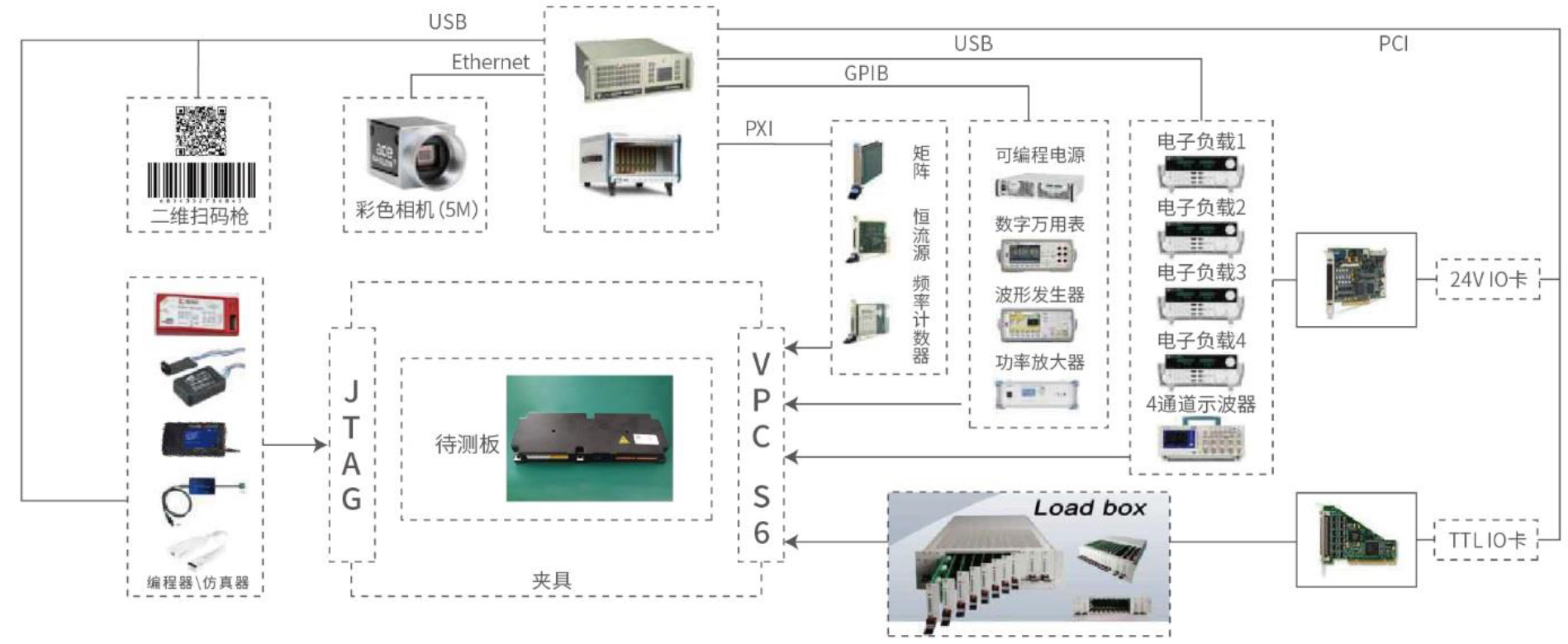

Overview of Testing System

The lPC-610 industrial computer of Advantech company is used as the main control part of the system.Agilent,Tektronix idexiand other brand instruments are integrated to build a flexible and high-precision test platform, and relay matrix loop switching function is included.We use 192 groups of programmable DC power supply to provide 192 groups of analog battery pack signals.The system can share important I & C hardware among different BMU + CSC + CVS products through interchangeable fixture, so as to greatly reduce the system cost and lead time. After the establishment of the basic system, we can quickly design and establish a new fixture and related test software.The software part uses NI LabVlEW + TestStand to write test software, provides hardware instrument driver, supports customer's secondary development function, and allows customers to update, relax or uparade test specifications without changing software through simple and convenient confiquration.The user interface is specially designed for the manufacturing environment, so it does not need too much human operation. The test engineer only needs to open the safety cover of the fixture,scan the product barcode of UUT, and then close the safety cover of the fixture to start the test during the standard operation. When the test is completed, the test results and test data will be displayed and recorded as files.

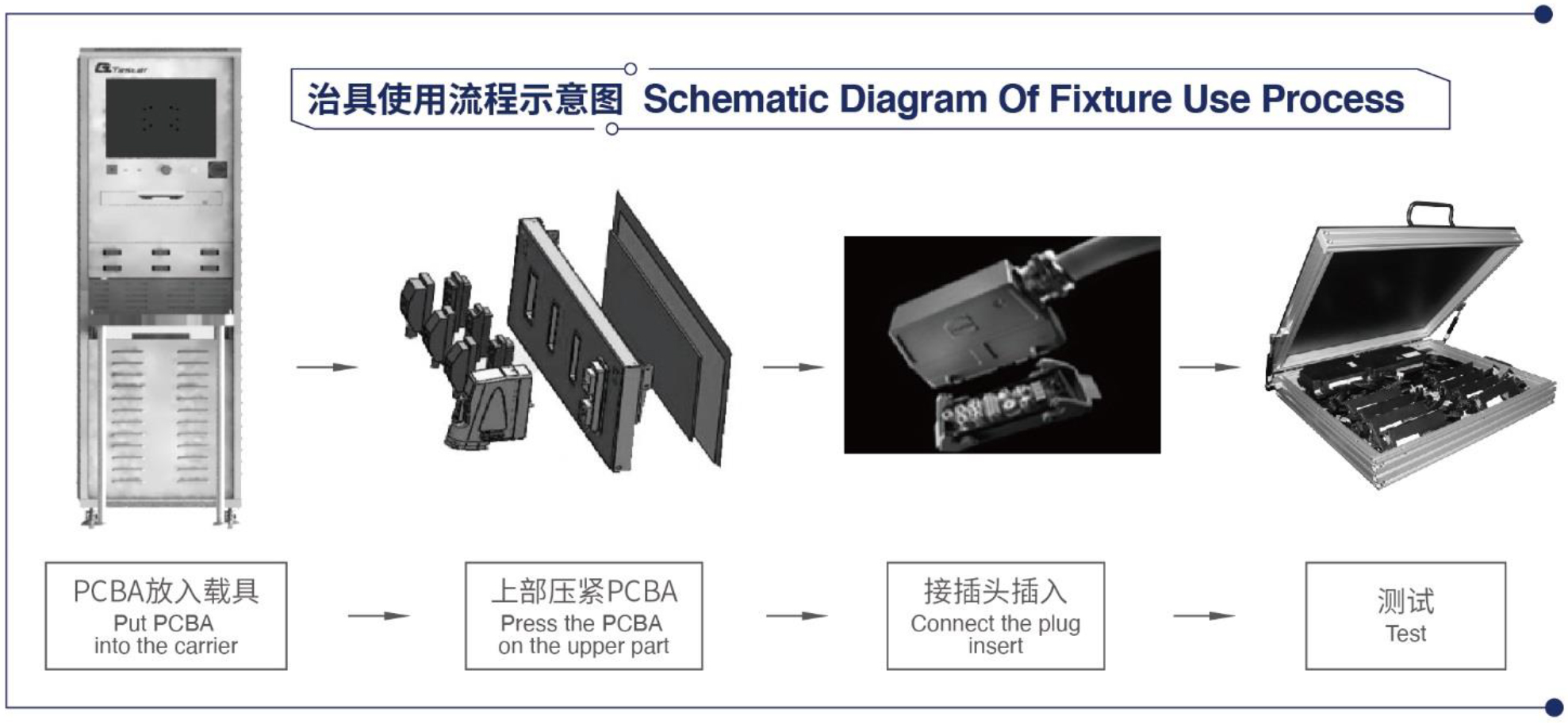

Diagram of test system

Test software main interface

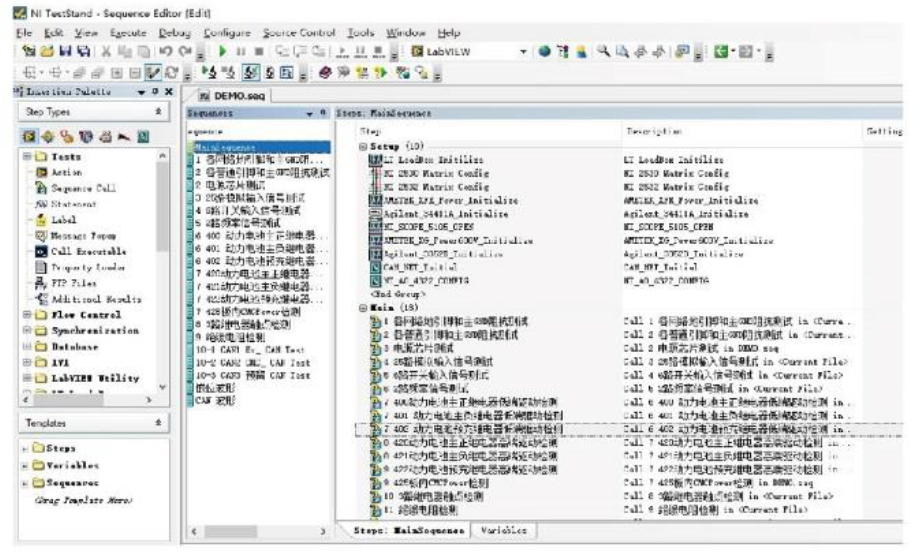

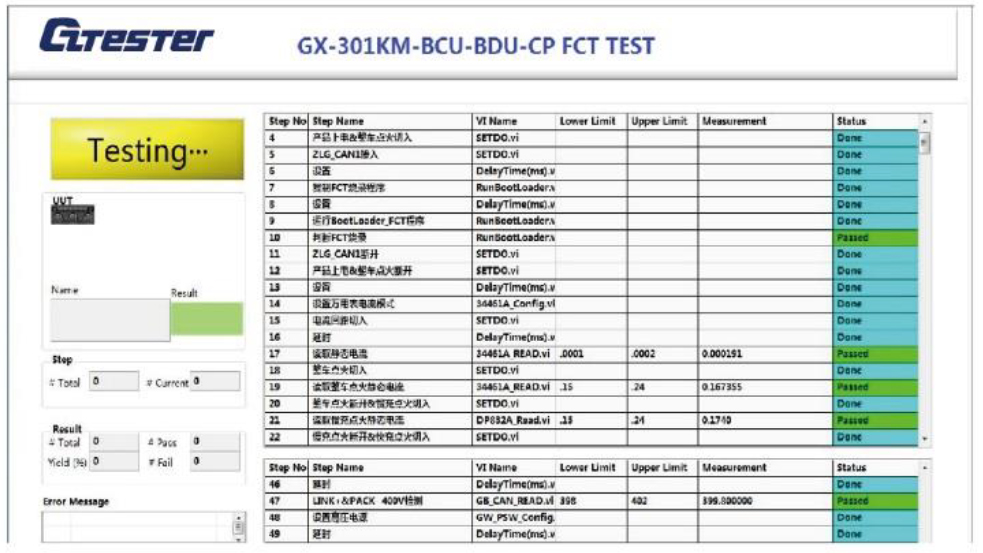

Testing software - BMS testing sequence interface