Automotive Electronics

Escort for safe driving

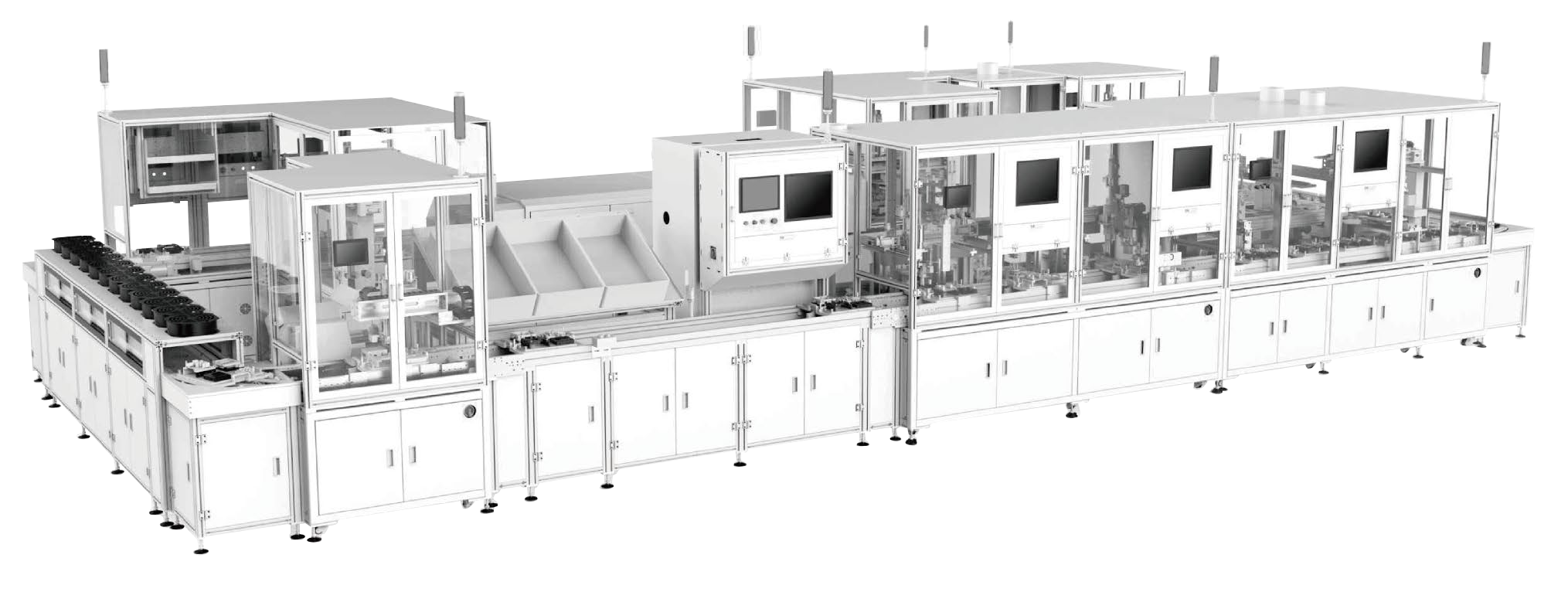

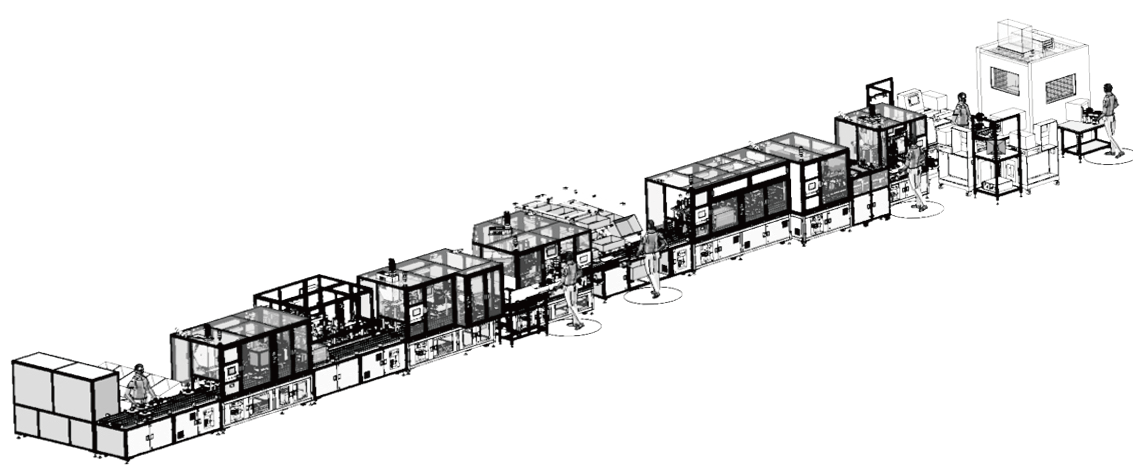

According to customer's requirement, for example material incoming, flow chart and cycle time, we provide different layout such as U shape, L shape, straight shape, hollow square and so on.

-

Sensor

-

Controller

ECU

ECU AVM

AVM -

Actuator

BLDC

BLDC Value

Value

-

Automotive Electronics

-

-

- Successfully delivered projects to multiple EPS Tier1 clients.

- Witnessed three different stages of EPS development: ECU and motor separation, combination, and integration.

- Experienced multiple clients with different process designs, such as PCBA screwlocking or hot riveting, motor UVW three pin soldering or resistance soldering.

- Local & MES storage of production data for easy traceability.

- Batch loading of assembly materials; Same loading and unloading station.

- According to customer's material incoming method, process route, CT requirements, and site planning, there are different layouts such as U-shaped, L-shaped, straight, andzigzag.

- Provide semi-automatic and fully automatic solutions according to different customerproduct requirements.

-

-

- Adopting platform based design to improve design, procurement, and assemblyefficiency, and shorten delivery time

- Fool proofing ensures the quality of the production process.

- The core processes include: terminal resistance welding, in-line dispensing, servopress-fitting, screw locking, motor load in-line testing, noise testing, offline dynamicbalancing testing, all of which have core parameter inspection and calibrationfunctions.

- Our self-developed servo press is capable of monitoring the force displacement duringpressing process and outputting graph, with reliable performance at optimized cost.

- The entire process data can be traced back to MES.

-

-

- The equipment is designed for operator standing operation;

- After the operator puts the product into the copy vehicle, manually connect the connector, press the start button with both hands at the same time, and the device enters the automatic operation stage;

- After the completion of the test, pull out the plug-in manually, the operator will take out the test product, and complete the material separation according to the test results;

- The equipment is equipped with a material recovery port for FAIL parts, and a regional light screen is installed to ensure that FAIL materials can be completely recovered.

- Repeat the above operations to complete the testing of each product.

-

- Standardized & Flexible & Modularized Station

- Quick Change ToolType for Multi-Productions

- Pick-up & Ass'y by Yamaha Robot and Cognex Align Vision installedon Robot Head for Aligning during Ass'y and Inspection before pick-up

- Cognex Align Vision installed on Station Base for Aligning during Ass'y

- Cognex Test Vision installed on Station Base for inspection after Ass'y

- Error-proofing design before Pick-up and after Ass'y by Cognex Vision System

- Main Ass'y Process of Shield CVR & 2 PCBA Ass'y - Insertion Force Monitoring & Stroke Display

- Auto Tray Charger System for housing& PCBA supply

- SMT Reel Feeder for Foam/Shield CVR etc.

- Transfer FlXJlG &Two-Robot collaboration concept for improving C/T

- In-Out Lift & Pallet ConveyorSystem& MES Communication

-